Description

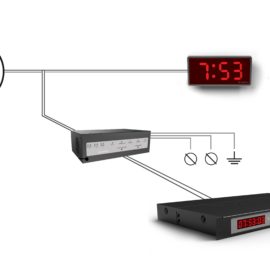

General

The conveyor system shutters meet the provisions of the general technical approval issued by the German Institute for Constructional Engineering Berlin. In accordance with that approval the following basic set-up arises.

Types of design

The conveyor system shutters may be designed single-leaved or double-leaved.

The closing elements may be designed either in one piece or as segment construction. As far as the closing direction is concerned a distinction is made between:

- vertically closing top down with mass balance or

- vertically closing from bottom up with closing weights or

- horizontally closing from left to right respectively from right to left or

- in case of two-leaved design horizontally centrally closing from both sides.

The conveyor system shutters are always self-closing, in their basic design they close by means of permanently stored mechanical energy (overweight, closing weight).

As far as the connection to the adjacent building components is concerned a distinction is made between the installation on a wall with four-sided overlapping (installation in raised position) and the floor-level installation with three-sided overlapping.

Closing element, closing element segment

The closing element respectively segment which is approx. 38 mm and approx. 58 mm thick consists of a steel profile frame filled in with non-inflammable material and is covered with non-inflammable panels on both sides and can, in addition to that, optionally be covered with steel sheet 1 mm thick.

As to the segment type construction individual segments are strung together. Each of the heading joints are on both sides covered with bands made of an un-flammable material; in addition to that a covering with sheet steel 1 mm thick may be applied.

Guiding

Guiding of the closing element is realized by means of guide elements, like for example sliding block, rolling cart, running wheel in or on a guide rail (e. g. HELM-rail), that shall be fixed on the adjacent building components.

The guide rails and the wall fixing angles are dimensioned dependent on the dimension and the weight of closing element.

In case of a horizontally closing conveyor system shutter with floor-level installation the lower guiding is realized by means of laterally arranged guide rolls.

A fire shutter closing top down with floor-level on-the-wall installation closes on the floor.

In case of vertically closing shutters as of a clear shutter width of 2000 mm and in case of horizontally closing shutters as of a clear shutter height of 2000 mm a backside clamping is provided for.

The vertically top-down closing shutters and the double-leaf type with horizontally closing direction (centrally closing) are equipped with a thermally tripping interlocking.

Sealing segment, sealing block (fixed sealing block)

The sealing of the shutter happens above the conveyor by means of sealing segments arranged on the closing element and below the conveyor and in the space between the conveyor profiles respectively in the conveyor profiles by means of sealing blocks.

The sealing segments consist of stripes of inflammable material which are laid on top of each other. In the remaining gaps stripes of an intumescent material are placed according to the clearance table.

In case of shutters for chain, roller or belt conveyors the closing element is equipped with an additional sealing segment. The spaces besides, below and within the conveyor are filled up with a sealing block as described above.

In case of a shutter for a hanging monorail conveyor plant with steel rail (Power & Free) or with aluminium rail, the sealing segment mounted on the closing element encloses the conveyor on all sides.

For sealing spaces opposite the moving direction of closing element movable flap sealing segments are applied. The flap sealing segment is mounted on the closing element by means of a hinged joint and is equipped with a thermal release mechanism. That ensures that in case of a fire the flap sealing segment swings in the conveyor not until after the closing of the closing element.

The shutter can also be penetrated by two conveyors running one above the other.

Accessories

For the shutter accessories in compliance with the „Construction Characteristics for Manufacture Monitoring” may be applied.

Reviews

There are no reviews yet.